Catalog of Screw Compressor

Catalog of Screw Compressor

|

Load condition(%) |

General screw air compressor electricity(Kwh) |

SRCvsd air compressor consumption(Kwh) |

Energy saving(Kwh) |

Efficiency(%) |

|

25 |

100 |

40 |

60 |

60 |

|

50 |

100 |

50 |

50 |

50 |

|

75 |

100 |

70 |

30 |

30 |

|

100 |

100 |

90 |

10 |

10 |

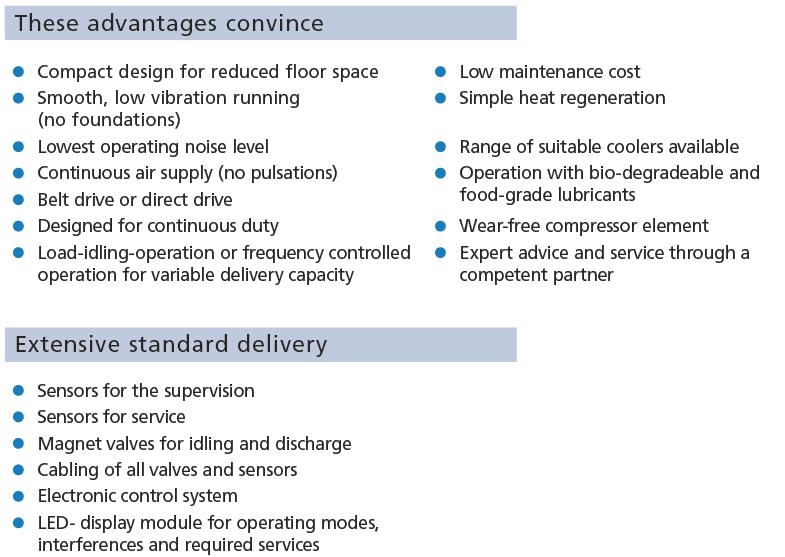

When buying air compressors, the traditional cost (ie, cost of purchase + maintenance costs), the proportion of only 25% of the total cost, while the energy consumption accounted for 75%. Ordinary (frequency) air compressor than ordinary (power frequency) air compressor energy saving 22-30%; Shanghai Rotorcomp variable frequency air compressor than ordinary (power frequency) air compressor energy saving 33-40%. (best screw air compressor for sale)

1. A 75KW ordinary air compressor, running 8000 hours a year, electricity 0.62 yuan / kWh, a year of electricity for the 75KW × 8000h × 0.62 yuan / (kw × h) = 372,000 yuan

2.Shanghai Rotorcomp VSD 75KW high energy-saving compressor, a year can save 35% of the electricity, a total of 372,000 yuan × 35% = 130,200 yuan;

3.The investment return period is about one year.

Running 8000 hours a year of rotorcomp energy efficient air compressor, power saving:

|

Power(KW) |

7.5 |

11 |

15 |

18.5 |

22 |

37 |

45 |

55 |

75 |

90 |

110 |

132 |

160 |

250 |

|

Power saving(kw/h) |

21000 |

30800 |

42000 |

51800 |

61600 |

103600 |

126000 |

154000 |

210000 |

252000 |

308000 |

369600 |

448000 |

700000 |

Efficient cooling fan

Efficient cooling fan

Intake valve

Intake valve Efficient oil and gas separation

Efficient oil and gas separation Chinese and English LCD display control

Chinese and English LCD display control High efficiency oil filter

High efficiency oil filter Air-cooled models - large area efficient cooling

Air-cooled models - large area efficient cooling Elastic coupling

Elastic coupling Body shock absorber

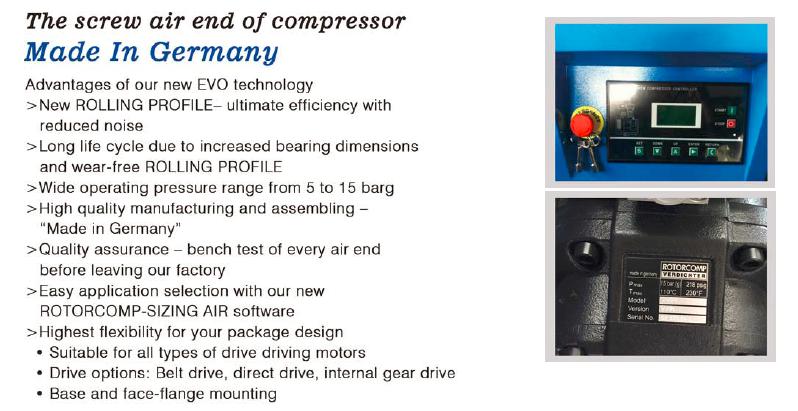

Body shock absorber The world's top screw host, high efficiency, low speed, the rotor with the third generation 5: 6 tooth, the world's best profile design, low noise, low power consumption, low maintenance costs, the best reliability and usability.

The world's top screw host, high efficiency, low speed, the rotor with the third generation 5: 6 tooth, the world's best profile design, low noise, low power consumption, low maintenance costs, the best reliability and usability.